Komet®: 100 Years of Excellence

Komet turned 100 years in 2023 – a reason to celebrate. Over the past century, Komet has evolved from a small company in Lemgo, Germany, into an internationally recognized expert in the dental industry.

Starting with the production of rotary dental instruments, Komet continuously developed and enhanced their products and expanded their product portfolio, setting new standards for the optimal treatment of your patients.

Quality, Innovation, Reliability

For more than 100 years, Komet has been a reliable partner for dentists and dental technicians worldwide. Throughout this time, they have impressed their customers with an extensive expertise in the industry and an in-depth understanding of their needs. Join Komet on a journey through history and see how the company has been preparing for the future with the spirit of innovation and unfailing drive since the foundation of the company!

How It All Began

Founded in 1923, the company Gebr. Brasseler* produced the first rotary dental instruments under the Komet brand; the circumstances were anything but rosy. In addition to the generally prevailing inflation and unemployment, already established manufacturers made it difficult to enter the market by blocking the specialized trade.

But Komet quickly recognized the opportunities offered by direct sales, thus laying the foundation for close contact with its customers. The concept soon proved to be successful. Only a few years after publishing the first printed catalogs in Düsseldorf, Komet built connections with international markets where they presented

themselves as an up-and-coming, promising company.

The brand name Komet was featured on the first advertising material. The idea for the brand name was born out of observing the first burs at work; when viewed in the light, the material removed by rotary instruments produces a tail that looks a lot like the tail of a comet in the sky. Today, the quality products made by Komet are synonymous with innovation, precision, and reliability – all over the world.

"The circumstances can never be so adverse that they cannot be overcome by a better performance."

A New Chance for Growth

Komet was not spared from the ravages of the Second World War. The production facility in Düsseldorf lay in ruins. However, this was no reason for the company to admit defeat: With ambition, courage, and hope, Komet focused rebuilding in 1943 in Lemgo, Germany, where they had found a new home.

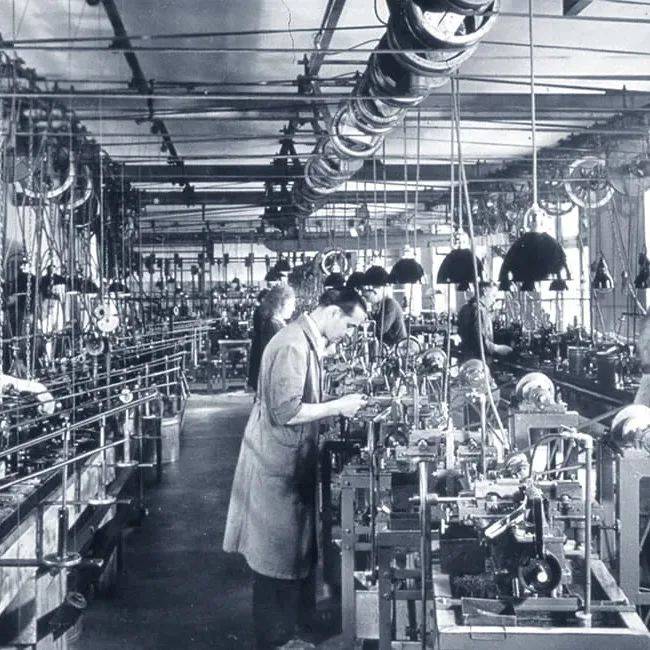

1949 Komet production line in Lemgo.

A Decade of Innovation

The 1950s were booming with innovation: The economy had recovered from the consequences of the war and more and more young people were being systematically trained as skilled workers.

Komet took advantage of the economic upswing and established itself as a driving force for new products, new technologies, and the use of new materials. As one of the first manufacturers, Komet began producing instruments made of tungsten carbide as early as 1956. Komet made the material’s special cutting ability and durability available to their customers.

All Set for the Next 50 Years

In 1973, Komet raised a glass to the 50th anniversary of the company. After 50 years, during which Komet had demonstrated their expertise worldwide and participated in numerous trade fairs at home and abroad, the question was what is the secret of their success?

Komet did not have to think long about the answer. Their achievements are owed to the intensive contact with their partners, the direct and competent advice they give to the customers, and their constant focus on the future. Komet firmly believes that only customer-oriented work can lead to satisfactory results.

Exploration of International Markets

In the years that followed, Komet grew continuously – Komet products made in Germany were also well received internationally. Based on this continuous growth beyond the borders of Germany, Komet high-quality dental rotary instruments reached dental professionals in France (1977), Italy (1986), Austria (2002), the USA (2007), and Canada (2019). Dentists and dental technicians from almost 100 countries can now purchase Komet instruments for more efficient treatments.

Komet achieved a lot in the past years. In addition to building an international brand identity, entering new markets, and modernizing the company, Komet has established themselves as an expert at home and abroad – dentists and dental technicians around the world trust the quality of Komet products.

Komet has achieved all this by remaining true to their values: the constant striving to improve and develop their instruments to provide dental professionals and patients alike with the best possible treatment.

As a driving force in the dental industry, Komet’s numerous ideas and products have changed dentistry.

2023 Komet manufacturing facility.

Komet Game-Changers

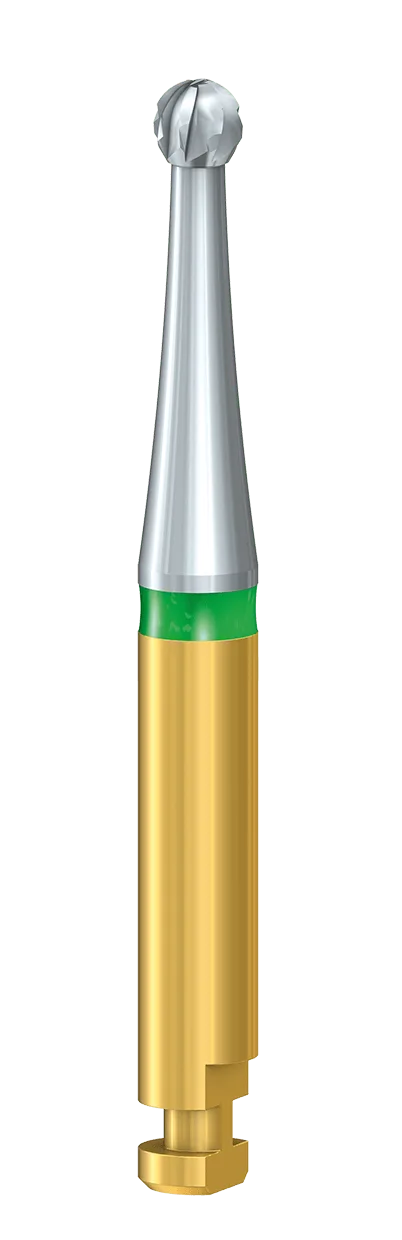

First tungsten carbide bur with staggered toothing

Komet has been manufacturing burs made of tungsten carbide since the 1950s. This material enables the production of instruments with sharper and more precise cutting edges. In 1980, Komet experts presented the first carbide drills with staggered toothing.

The introduction of this new manufacturing technology made it possible to produce smooth-running dental instruments that remove dental material efficiently while leaving a smooth surface on the tooth.

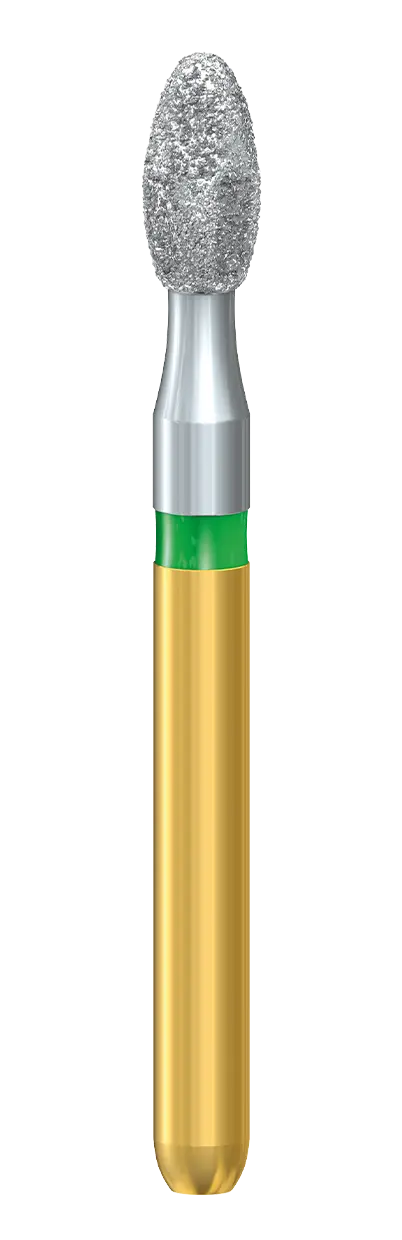

S-Diamonds®

In 2001, Komet developed a time-saving solution for crown preparation: S-Diamonds for gentle, yet efficient treatments. Thanks to the unique combination of a structured blank and coarse diamond grit, these instruments remove dental substance with great efficiency.

Q-Finishers®

The innovative cross-cut toothing of the Q-Finishers made by Komet revolutionized the processing of composite fillings in 2003. Whereas traditional treatments required three steps, Q-Finishers can do the job in only two – for effective, yet time and cost-saving finishing.

K1SM – CeraBur®

In 2007, Komet put another innovation on the market: the K1SM is a ceramic bur that enables minimally invasive excavation with particularly high precision. It is also distinguished by its impressively long service life. Thanks to its smooth, almost vibration-free operation, the K1SM is a particularly popular choice for the treatment of children.

Looking Ahead

Komet will continue to incorporate the experience gained over the past 100 years into the development of new instruments and solutions in the future. At the same time, Komet will remain in close exchange with dental community – to prepare together for the world of tomorrow.

Interested in learning more? Request an Appointment with a Clinical Advisor in your area or a customized Bur Audit. We are here to help!

* Not to be confused with Brasseler USA.

Discover More

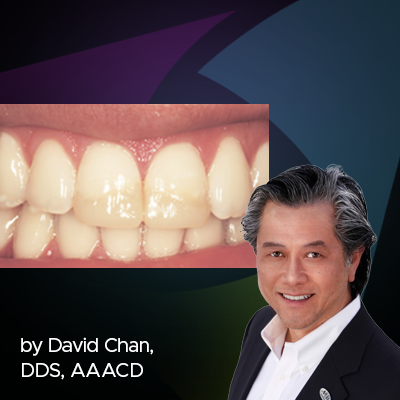

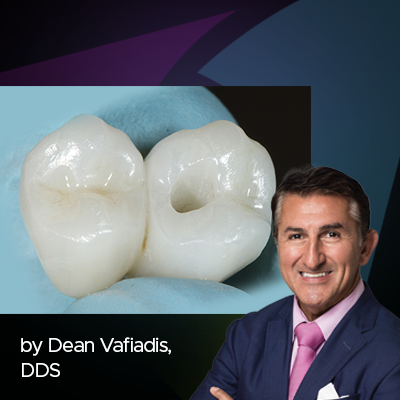

This article was originally published in the Clinical Life™ magazine: Fall 2023 edition

Clinical Life™ magazine is a premier periodical publication by Clinical Research Dental Supplies & Services Inc. Discover compelling clinical cases from Canadian and US dental professionals, cutting-edge techniques, product insights, and continuing education events.

Access all previous publications, request printed editions, or subscribe to our newsletter today.

Join our thriving community of dental professionals and elevate your practice to new heights!